S54 Engine Long Block Service

Our S54 Engine long block service consists of a complete teardown, inspection and total overhaul of the engine.

Everything is washed in our high temp jet washer.

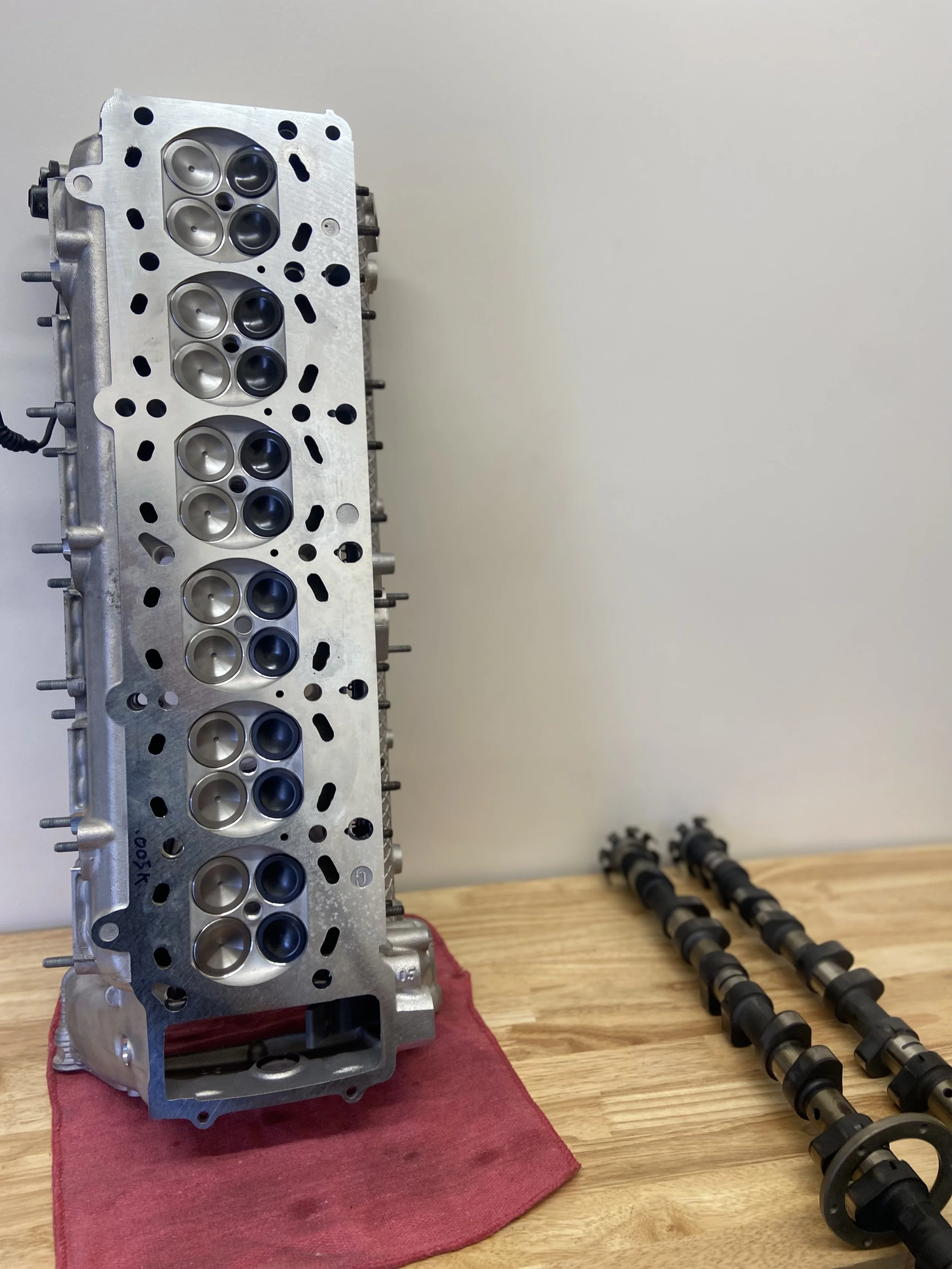

Head is then disassembled and inspected.

(Rockers, rocker shafts, valve springs, retainers, valves, camshafts, cam caps, cam bridge)

Block is disassembled and inspected.

(mains, oil squirters, head dowels, timing cover)

Crankshaft is washed, measured, polished, washed again and then final measured.

Connecting rods are a crack cap style, so they are unable to be resized.

(However they are typically good to be reused, if rods are unable to be reused you will be notified of your options)

When everything is cleaned and thoroughly inspected, we can then proceed with how we want to go about your engine build. We always start with a .010k over as it still leaves another rebuild cycle for then S54. Stock bore is 87mm, first over is 87.25mm (.010k), final bore is 87.5mm (.020k). When rebuilding a race engine you try and leave as many build cycles in it as possible. 87.5mm is as far as an S54 will go, after that its either the garbage or sleeve the whole block.

The block will be minimally surfaced (.003k is typically what we see an S54 needing, however different conditions and a harsher more abusive life could net more to be removed)

The block will be torque plate honed/bored (we use ARP head studs torqued to spec to emulate actual final assembly torque)

We will usually stock Mahle 87.25mm pistons, as well as JE 87.5mm as part of our inventory. However if a custom set of high compression pistons is required, lead times can often be up to 3 months if not more.

If building a stroker engine we recommend the block is align honed to guarantee a perfect starting ground for our new crank.

The head is completely gone through including: valve guides, valve job, polishing rocker shaft bores, surfacing the head, as well as optional porting for exhaust (recommended for supercharged, turbocharged, or high compression build).

Cutting seats for big valve heads is also an option, must be requested.

New +1mm valve will be ordered from Supertech + single groove keepers.

Choice of valve train is completely up to you. However with our build, Supertech nitride exhaust valves are part of this rebuild package.

If budget is of no concern, we highly recommend a complete Supertech valve train, using their new beehive valve spring kits along with titanium retainers as well as nitride intake valves, and inconel exhaust valves.

As the machine work wraps up, we begin turning our sights towards the balancing of internal components. Checking the weights of the rods, pistons, and rings, against each other.

Bearings that we use will typically depend on availability. We use; King bearings, Calico coated bearings, as well as ACL and Clevite.

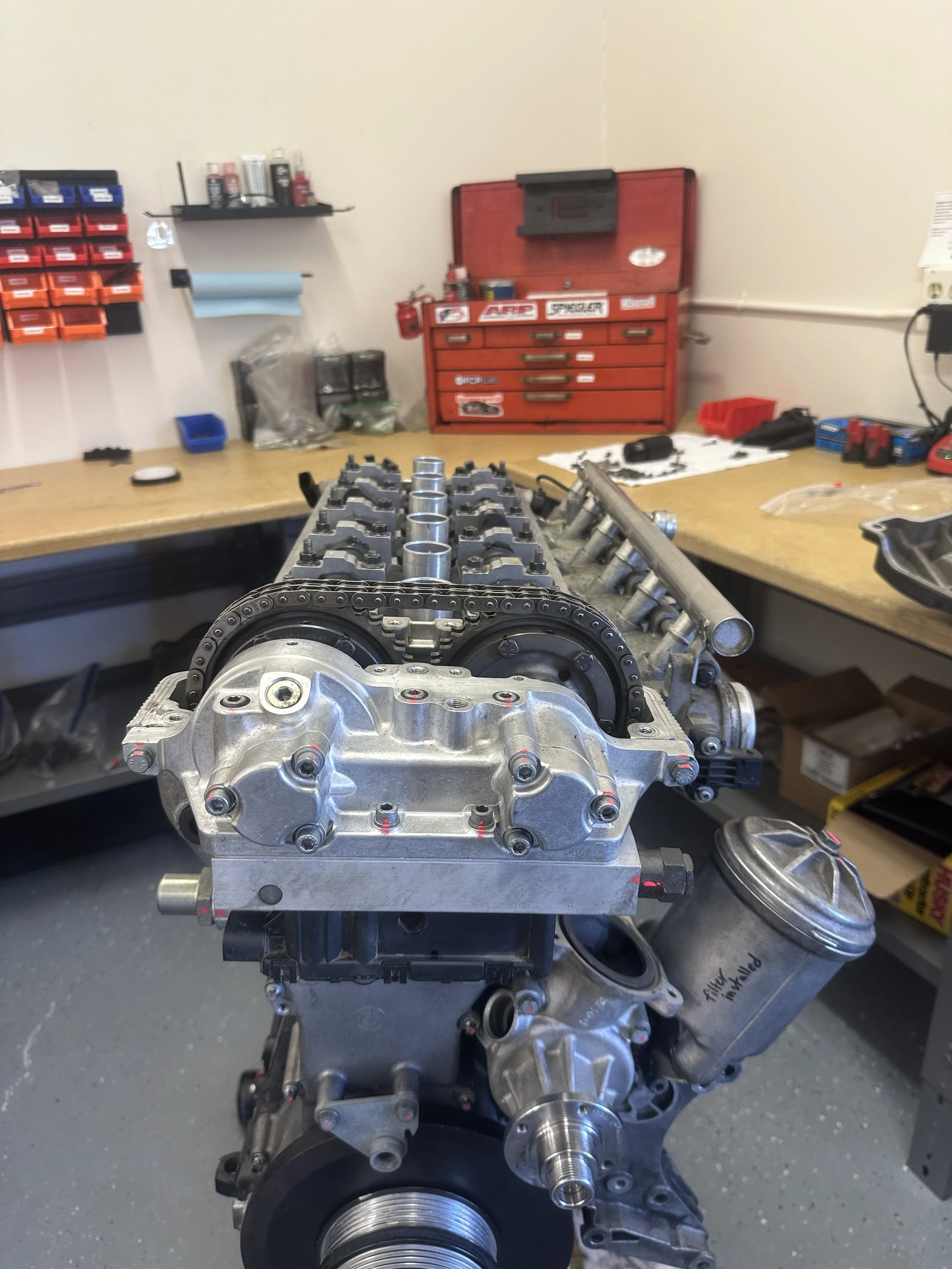

Assembly begins.

We use ARP fastener components in every place possible, main studs, rod bolts, and head studs. In a future rebuild these components can be reused. (Rod bolts will need stretch cycle management).

When reassembling the engines every component is replaced with a new one from timing chain, to guides, oil pan gasket, and plenty more.

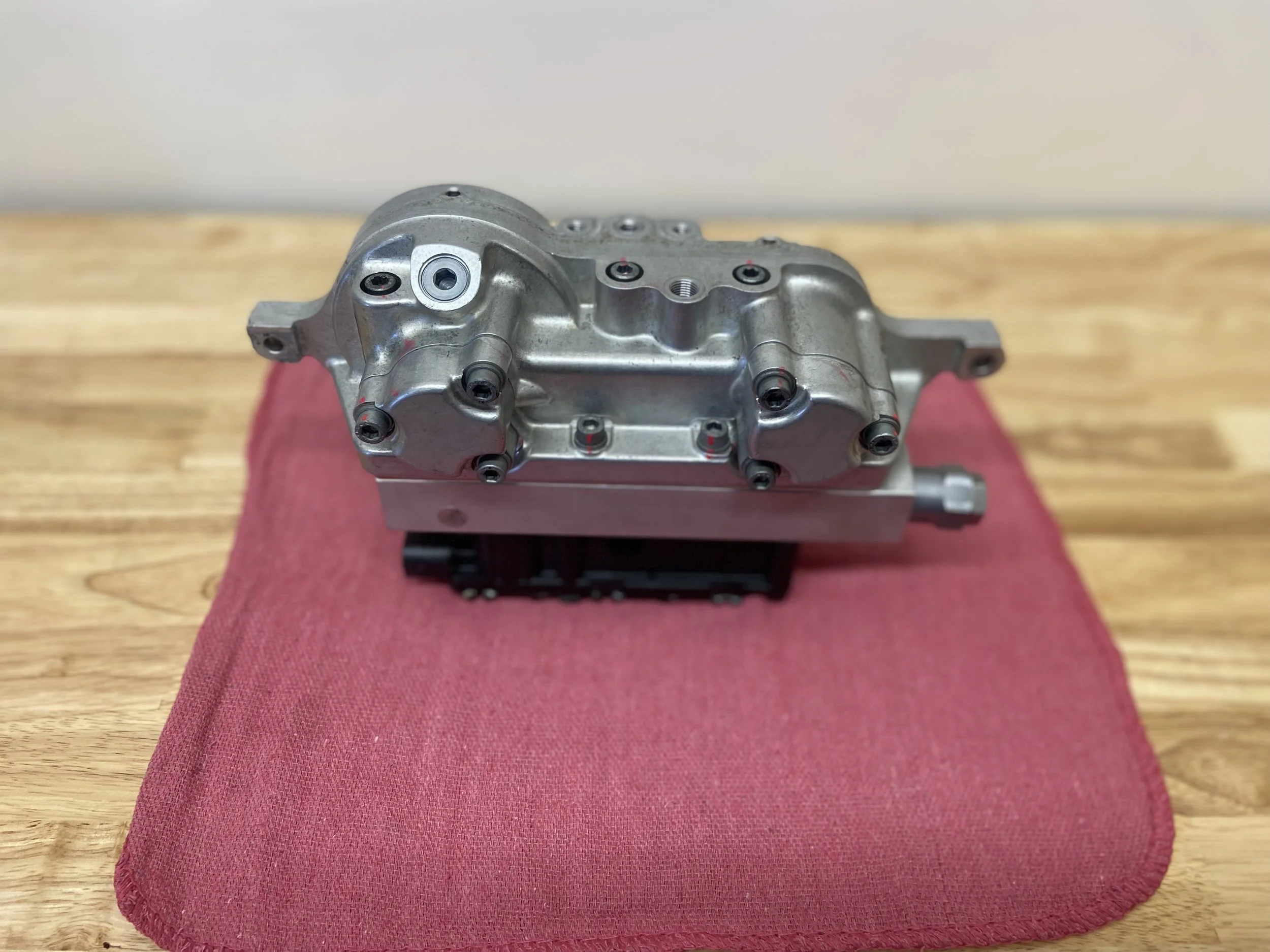

WE ONLY REPLACE OIL PUMPS THAT ARE IN NEED OF REPLACEMENT

We tear down and inspect every oil pump, measure for clearances, check for unusual wear, as well as check wear on the aluminum arm that is known for chain interference leading to a hole, obviously leading to oil pressure issues. If a hole has started it can be tacked and then ground.

We have no problem replacing oil pumps, but as an additional charge.

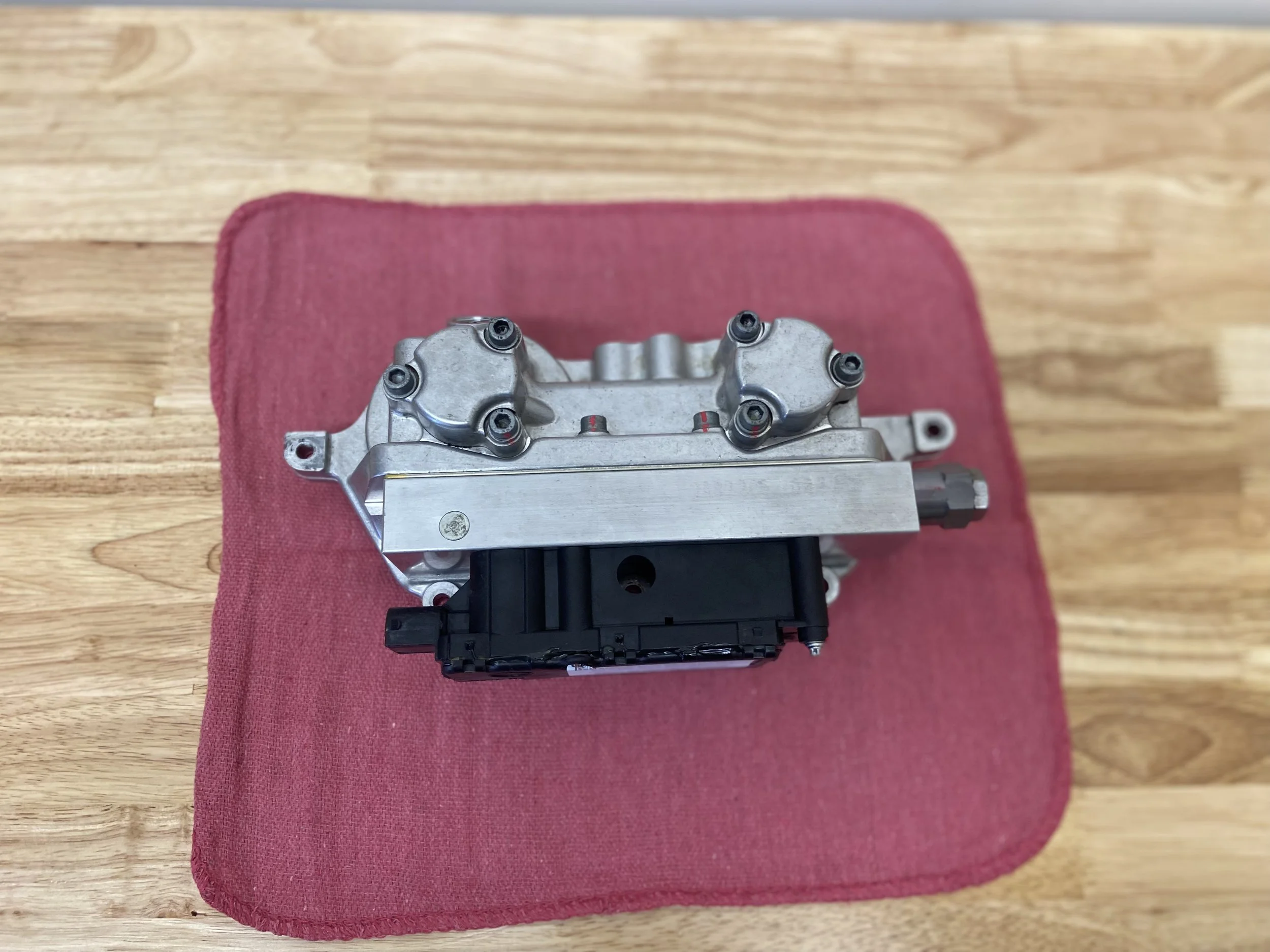

Our Vanos units are rebuilt in house using Beisan Systems components.

WE NEED TO START WITH A GOOD UNIT, IF IT IS LEAKING OIL PLEASE DO NOT SEND IT TO US WITHOUT STATING THERE WAS A EXISTING PROBLEM WITH IT.

If your unit is leaking we have units available for purchase.

Final assembly is underway.

Your engine will be delivered timed and ready for accessories

(We can do complete accessory assemblies at additional cost, however accessories need to be supplied, and additional shipping costs apply for additional sizing of package).

Our lead times depend heavily on parts availability.

If all parts are in stock expect lead times of 2-4 weeks for basic S54 refreshes.

Before an engine is accepted a 50% deposit as well as a firm plan for build direction.

If direction of build changes from S54 basic overhaul to; stroker, high compression, super duper race build, lead times will increase based on parts availability. Most parts are not on the shelf and are made to order. Subjects of cost will change.

If you are interested in building an “extreme race” S54 please reach out to us and we will PLAN something in advanced so we can be more efficient.

Our S54 Engine long block service consists of a complete teardown, inspection and total overhaul of the engine.

Everything is washed in our high temp jet washer.

Head is then disassembled and inspected.

(Rockers, rocker shafts, valve springs, retainers, valves, camshafts, cam caps, cam bridge)

Block is disassembled and inspected.

(mains, oil squirters, head dowels, timing cover)

Crankshaft is washed, measured, polished, washed again and then final measured.

Connecting rods are a crack cap style, so they are unable to be resized.

(However they are typically good to be reused, if rods are unable to be reused you will be notified of your options)

When everything is cleaned and thoroughly inspected, we can then proceed with how we want to go about your engine build. We always start with a .010k over as it still leaves another rebuild cycle for then S54. Stock bore is 87mm, first over is 87.25mm (.010k), final bore is 87.5mm (.020k). When rebuilding a race engine you try and leave as many build cycles in it as possible. 87.5mm is as far as an S54 will go, after that its either the garbage or sleeve the whole block.

The block will be minimally surfaced (.003k is typically what we see an S54 needing, however different conditions and a harsher more abusive life could net more to be removed)

The block will be torque plate honed/bored (we use ARP head studs torqued to spec to emulate actual final assembly torque)

We will usually stock Mahle 87.25mm pistons, as well as JE 87.5mm as part of our inventory. However if a custom set of high compression pistons is required, lead times can often be up to 3 months if not more.

If building a stroker engine we recommend the block is align honed to guarantee a perfect starting ground for our new crank.

The head is completely gone through including: valve guides, valve job, polishing rocker shaft bores, surfacing the head, as well as optional porting for exhaust (recommended for supercharged, turbocharged, or high compression build).

Cutting seats for big valve heads is also an option, must be requested.

New +1mm valve will be ordered from Supertech + single groove keepers.

Choice of valve train is completely up to you. However with our build, Supertech nitride exhaust valves are part of this rebuild package.

If budget is of no concern, we highly recommend a complete Supertech valve train, using their new beehive valve spring kits along with titanium retainers as well as nitride intake valves, and inconel exhaust valves.

As the machine work wraps up, we begin turning our sights towards the balancing of internal components. Checking the weights of the rods, pistons, and rings, against each other.

Bearings that we use will typically depend on availability. We use; King bearings, Calico coated bearings, as well as ACL and Clevite.

Assembly begins.

We use ARP fastener components in every place possible, main studs, rod bolts, and head studs. In a future rebuild these components can be reused. (Rod bolts will need stretch cycle management).

When reassembling the engines every component is replaced with a new one from timing chain, to guides, oil pan gasket, and plenty more.

WE ONLY REPLACE OIL PUMPS THAT ARE IN NEED OF REPLACEMENT

We tear down and inspect every oil pump, measure for clearances, check for unusual wear, as well as check wear on the aluminum arm that is known for chain interference leading to a hole, obviously leading to oil pressure issues. If a hole has started it can be tacked and then ground.

We have no problem replacing oil pumps, but as an additional charge.

Our Vanos units are rebuilt in house using Beisan Systems components.

WE NEED TO START WITH A GOOD UNIT, IF IT IS LEAKING OIL PLEASE DO NOT SEND IT TO US WITHOUT STATING THERE WAS A EXISTING PROBLEM WITH IT.

If your unit is leaking we have units available for purchase.

Final assembly is underway.

Your engine will be delivered timed and ready for accessories

(We can do complete accessory assemblies at additional cost, however accessories need to be supplied, and additional shipping costs apply for additional sizing of package).

Our lead times depend heavily on parts availability.

If all parts are in stock expect lead times of 2-4 weeks for basic S54 refreshes.

Before an engine is accepted a 50% deposit as well as a firm plan for build direction.

If direction of build changes from S54 basic overhaul to; stroker, high compression, super duper race build, lead times will increase based on parts availability. Most parts are not on the shelf and are made to order. Subjects of cost will change.

If you are interested in building an “extreme race” S54 please reach out to us and we will PLAN something in advanced so we can be more efficient.